General

A transformer is a static electric device (that is, one free from rotating or moving parts) most often used to convert one alternating voltage to another alternating voltage (or other alternating voltages) at the same frequency by mutual induction.

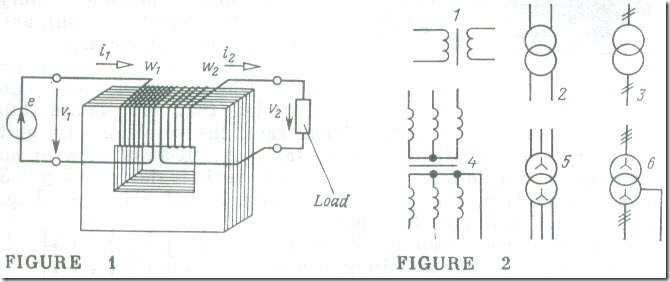

A transformer has at least two windings linked by a common magnetic flux but electrically insulated from each other (except in an autotransformer). In most transformers the windings are put on a core assembled from electrical-sheet steel laminations.

The purpose of the core is to enhance the inductive coupling between the windings, and the objective of using a laminated core is to reduce eddy currents (Fig. 1). No cores are used in air-cored transformers operating at frequencies above around 20 kHz, since the core is not magnetized all the same because of a marked increase in eddy currents.

The transformer winding connected across a supply source (which may be a power line, a generator, etc.) is called primary. All the quantities associated with this winding are also called primary (the primary turns, the primary voltage, the primary current, etc.), and their symbols are indexed "1", for example, w1 , v1 , i1 (see Fig. 1). The transformer winding connected across a load is called secondary, and all the quantities associated with it are referred to as secondary and indexed "2".

Transformers may be single-phase (for single-phase circuits) and three-phase (for three-phase circuits). In a three-phase transformer, the primary or secondary winding refers to the three phase windings carrying the respective (primary or secondary) voltage. The graphical symbols most widely used in the USSR for single-phase transformers (1, 2, 3) and for three-phase transformers (4, 5, 6) are shown in Fig. 2.

Each transformer has a nameplate which bears all of its ratings. These include the voltage on the high-voltage (H. V.) side, the voltage on the low voltage (L. V.) side; its apparent power (in VA or kVA); its current (in A) at the rated apparent power; the frequency; the number of phases; the phase interconnection; its duty (long-term or short-term); and the method of cooling.

According to the manner in which transformers are cooled, they are classed into dry and oil-immersed. In the latter case, the core-and-coils unit is immersed in an oil-filled steel tank. A cut-away view of an oil-immersed transformer with a tubular tank is shown in Fig. 3 where 1 is the core, 2 is the L.V. winding, 3 is the H.V. winding, 4 are the H.V. terminal bushings, 5 are the L.V. terminal bushings, 6 is the tubular tank, 7 is the oil-filling cock, 8 is the explosion stack, 9 is the Buchholtz gas relay, 10 is the oil conservator, and 11 is the oil drain cock.

If the primary voltage V1 is lower than the secondary voltage V2 we have a step-up transformer; otherwise ( V1 > V2 ) we have a step-down transformer.

Figure 4 shows the distribution of power in a transformer. Here P1 is the power in the primary winding; Pc,1 is the copper loss in the primary winding; P1 is the iron (or core) losses which include both hysteresis losses and eddy-current losses; P1 - Pc,1 - P1 = = P12 is the power in the secondary winding which includes Pc,2 or the copper losses in the secondary, with the remainder P2 being the power supplied by the transformer to the associated load, such that P2 = P12 - Pc,2 = P1 - Pc,1 - P1 - Pc,2 . In operation Under rated conditions, the difference P1 - P2 or the total losses in .the transformer, accounts for as little as 1-2 % of the rated power in the primary winding. In the diagram, the loss fraction is shown exaggerated for better presentation.

A single-phase transformer operates in practically the same way as one phase of a three-phase transformer. Therefore, in order to simplify the presentation, we will first analyse the operation of a two-winding, single-phase transformer, and the findings will then be extended to include what concerns three-phase transformers only.

Labels: Electricity and Magnetism