COUNTER EMF

While a dc motor is running, it acts somewhat like a dc generator. There is a magnetic field from the field poles, and a loop of wire is turning and cutting this magnetic field. For the moment, disregard the fact that there is current flowing through the loop of wire from the battery. As the loop sides cut the magnetic field, a voltage is induced in them, the same as it was in the loop sides of the dc generator. This induced voltage causes current to flow in the loop.

Now, consider the relative direction between this current and the current that causes the motor to run. First, check the direction the current flows as a result of the generator action taking place (view A of fig. 2-2). (Apply the left-hand rule for generators which was discussed in the last chapter.) Using the left hand, hold it so that the forefinger points in the direction of the magnetic field (north to south) and the thumb points in the direction that the black side of the armature moves (up). Your middle finger then points out of the paper (toward you), showing the direction of current flow caused by the generator action in the black half of the armature.

This is in the direction opposite to that of the battery current. Since this generator-action voltage is opposite that of the battery, it is called "counter emf." (The letters emf stand for electromotive force, which is another name for voltage.) The two currents are flowing in opposite directions. This proves that the battery voltage and the counter emf are opposite in polarity.

At the beginning of this discussion, we disregarded armature current while explaining how counter emf was generated. Then, we showed that normal armature current flowed opposite to the current created by the counter emf.

We talked about two opposite currents that flow at the same time. However, this is a bit oversimplified, as you may already suspect. Actually, only one current flows. Because the counter emf can never become as large as the applied voltage, and because they are of opposite polarity as we have seen, the counter emf effectively cancels part of the armature voltage. The single current that flows is armature current, but it is greatly reduced because of the counter emf.

In a dc motor, there is always a counter emf developed. This counter emf cannot be equal to or greater than the applied battery voltage; if it were, the motor would not run. The counter emf is always a little less. However, the counter emf opposes the applied voltage enough to keep the armature current from the battery to a fairly low value. If there were no such thing as counter emf, much more current would flow through the armature, and the motor would run much faster. However, there is no way to avoid the counter emf.

Q.4 What causes counter emf in a dc motor?

Q.5 What motor characteristic is affected by counter emf?

MOTOR LOADS

Motors are used to turn mechanical devices, such as water pumps, grinding wheels, fan blades, and circular saws. For example, when a motor is turning a water pump, the water pump is the load. The water pump is the mechanical device that the motor must move. This is the definition of a motor load.

As with electrical loads, the mechanical load connected to a dc motor affects many electrical quantities. Such things as the power drawn from the line, amount of current, speed, efficiency, etc., are all partially controlled by the size of the load. The physical and electrical characteristics of the motor must be matched to the requirements of the load if the work is to be done without the possibility of damage to either the load or the motor.

Q.6 What is the load on a dc motor?

Back

Home

Up

Next

PRACTICAL DC MOTORS

As you have seen, dc motors are electrically identical to dc generators.

In fact, the same dc machine may be driven mechanically to generate a voltage, or it may be driven electrically to move a mechanical load. While this is not normally done, it does point out the similarities between the two machines.

These similarities will be used in the remainder of this chapter to introduce you to practical dc motors. You will immediately recognize series, shunt, and compound types of motors as being directly related to their generator counterparts.

SERIES DC MOTOR

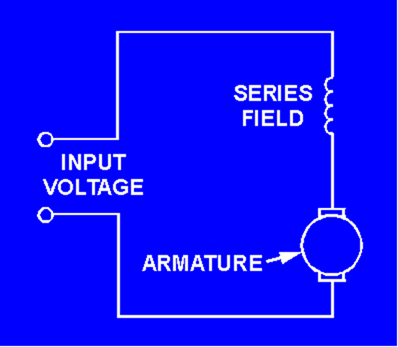

In a series dc motor, the field is connected in series with the armature. The field is wound with a few turns of large wire, because it must carry full armature current. The circuit for a series dc motor is shown in figure 2-3.

Figure 2-3. - Series-wound dc motor.

This type of motor develops a very large amount of turning force, called torque, from a standstill. Because of this characteristic, the series dc motor can be used to operate small electric appliances, portable electric tools, cranes, winches, hoists, and the like.

Another characteristic is that the speed varies widely between no-load and full-load. Series motors cannot be used where a relatively constant speed is required under conditions of varying load.

A major disadvantage of the series motor is related to the speed characteristic mentioned in the last paragraph. The speed of a series motor with no load connected to it increases to the point where the motor may become damaged. Usually, either the bearings are damaged or the windings fly out of the slots in the armature. There is a danger to both equipment and personnel.

Some load must ALWAYS be connected to a series motor before you turn it on.

This precaution is primarily for large motors. Small motors, such as those used in electric hand drills, have enough internal friction to load themselves.

A final advantage of series motors is that they can be operated by using either an ac or dc power source. This will be covered in the chapter on ac motors.

Q.7 What is the main disadvantage of a series motor?

Q.8 What is the main advantage of a series motor?

Back

Home

Up

Next

ANSWERS TO QUESTIONS Q1. THROUGH Q16.

A1. Direction of armature current, and direction of magnetic flux in field.

A2. Direction of conductor movement (rotation), direction of flux, and the direction of current flow.

A3. There are no differences.

A4. Generator action.

A5. Speed.

A6. The device to be driven by the motor.

A7. It must have a load connected to avoid damage from excess speed.

A8. High torque (turning force) at low speed.

A9. It maintains a constant speed under varying loads.

A10. Only outside of coils cut flux (inefficient).

A11. By winding the armature in a way that places the entire coil where it is exposed to maximum flux.

A12. By reversing either field or armature connections. A13. Motor will slow down. A14. Opposite the rotation.

A15. Armature current.

A16. To limit armature current until counter emf builds up.

Back

Home

Up

Next

Labels: Direct current motors