Valve settings

Valve settingsAs previously stated, there may be more than one fault in a system and some may persist until such time as a total breakdown or component failure occurs, to the detriment of the product being stored.

For example, after a leak has been discovered and repaired, the system is ready to be charged with refrigerant: reference has already been made to a check of operating pressures and a full sight glass as indications that the system is fully charged. However, this does not necessarily mean that the evaporator is correctly flooded and is operating to its full capacity. To make certain of this, the superheat setting of the expansion valve must be checked. An incorrectly adjusted valve can lead to starvation of liquid refrigerant to the evaporator, or to flooding of the evaporator with the possibility of liquid refrigerant entering the compressor to cause damage.

There is also the possibility of a restricted refrigerant flow, which again will result in starvation of liquid to the evaporator.

Other faults, less evident when an engineer is in attendance, can come to light after the repair: refrigerant leakage from a shaft seal may be due to another component failure; an inefficient compressor can lead to loss of duty and extended running time, with unnecessary expense to the customer.

Checking a compressor operation is simple, but will entail adjustment of some controls (see page 51).

The various faults and symptoms are dealt with in this chapter.

It is recommended that a quick acting indicating thermometer be used. Two thermometer probes must be firmly attached to pipework free of frost or ice to ensure good thermal conductivity, one at the evaporator inlet and the other as close as possible to the thermal element or bulb of the expansion valve (see

Figure 18). The temperature of the refrigerant passing through the pipework at these two points can now be quickly and accurately taken.

The temperature difference between the two points is the amount of super- heating taking place within the evaporator. A very wide differential means that the coil is starved of liquid and subject to excessive superheating, and that the evaporator is not fully active. Very little or no temperature difference means very little superheating; the evaporator is fully active over its entire surface, but some frosting back could occur at certain times during the system operation.

It is important that the expansion valve is adjusted to give the correct amount of superheating during commissioning, when a replacement has been made and, as good insurance, when a system has been charged.

Generally the performance of the thermostatic expansion valve depends upon the correct location of the thermal bulb. This should be clamped firmly to a horizontal section of the suction line near to the evaporator outlet if possible, and preferably within the refrigerated space. The entire length of the bulb should make good thermal contact with the pipework, as illustrated in Figure 18.

The location of the bulb relative to the diameter of the tubing is also important. It must never be located on the underside of the pipework, where it will register false temperatures because of the presence of oil in the pipework.

Manufacturers will stipulate the setting of new expansion valves. They are generally set to maintain a superheat of 3.5 to 5 °C or 7 to 9 °F.

Different evaporators require different settings of the valve to keep the coils correctly flooded. It is accepted that optimum operating conditions are achieved when thermostatic expansion valves are set to within the following: Dry expansion, gravity coil: 5 to 7 °C or 9 to 12 °F.

Forced air evaporator coil: 1.5 to 3 °C or 3 to 5 °F.

It is evident that if a factory set valve with a 7 °C setting is fitted to a forced air evaporator, too much superheating will take place. By adjusting the valve to within the accepted range, say 4 °C, less superheating will occur and the evaporator will be more efficient.

Figure 19 shows two conditions of the refrigerant in a gravity coil at different settings of the expansion valve.

Pressure drop: external equalizing

A low evaporating pressure can be due to pressure drop through the evaporator caused by friction, the length of the evaporator tubing, and the number of return bends employed in the evaporator design. If this occurs, the saturation temperature of the refrigerant may be lower at the outlet of the evaporator than at the inlet.

When an evaporator has a pressure drop in excess of 5 psig or 0.3 bar it is essential to employ a thermostatic expansion valve with an external equalizer. This type of valve is designed to compensate for pressure drop. The equalizer is a small tube or capillary which is connected beneath the expansion valve bellows or diaphragm; the other end is installed in the suction line at the outlet of the evaporator. In operation the equalizing tube provides the same pressure as that in the suction line at the thermal bulb location whilst the compressor is running. This equalizing of pressure will permit accurate superheat adjustments.

The expansion valve equalizing connection should be located 150 200 mm beyond the thermal bulb of the valve on the compressor side, as shown in Figure 20.

To further explain the significance of pressure drop and the need for the use of an external equalizing expansion valve, Figure 21 shows the effect of pressure drop with an internal equalizing expansion valve and how external equalizing compensates for the pressure drop. The calculations, pressures and temperatures are for refrigerant R12.

When flooding of the evaporator takes place, frosting along the suction line will be evident. This is caused by the liquid refrigerant boiling off and reducing the temperature of the suction line. Frosting along the suction line can also occur when there is a pressure drop through the evaporator and the suction line temperature is reduced to below 0 °C.

With low temperature applications the returning suction vapour may be at a temperature well below 0 °C, resulting in suction line frosting. It is common practice to insulate suction lines of low temperature installations in order to overcome this problem.

Some commercial evaporators are designed with series-parallel and parallel tubing circuits, which means that they have more than one refrigerant circuit. Refrigerant from a single outlet expansion valve is directed to the circuits by means of a distributor, which in most cases is part of the evaporator assembly. These exist in many forms; two types are shown in Figure 22.

A multi-outlet expansion valve can also be used to perform a similar func- tion, feeding two refrigerant circuits. Such a valve is shown in Figure 23.

There are a number of reasons for replacing an expansion valve:

1 Mechanical failure of the valve: possible seizure of the valve stem carriage; worn valve seat and letting by; defective or wrong sized valve orifice cartridge.

2 Partial loss of the thermal charge: insufficient pressure exerted by the power head in response to temperature changes, resulting in an erratic valve operation.

4 An excessive pressure drop across the evaporator is discovered: an external equalizing type has to be substituted.

When this condition exists there is effectively a total blockage in the high side of the system (liquid line). The pressure in the low side of the system may be negative, or that determined by the cut-out setting of the low pressure control.

The system is therefore ‘pumped down’ from the point of the blockage, in this case the expansion valve, and there is no need for the pumping down procedure to be carried out. There is, however, a liquid line full of liquid; unless an isolating valve has been installed, this liquid must be removed.

If there is a liquid charging valve at the receiver with an appropriate connector, it may be possible to transfer the liquid into an empty refrigerant cylinder. If not, it must be reclaimed. The following procedure should be adopted:

1 Isolate the plant electrically and close the liquid shut-off valve at the receiver.

2 Front seat the suction service valve.

3 Release the thermal bulb from the clamp at the outlet of the evaporator.

4 Ensure that the working area is well ventilated. If any food products are in the immediate vicinity they should be removed or covered as a protection against contamination.

5 Check the orifice size of the new valve, and check that it is suitable for use with the system refrigerant.

6 Remove the defective valve and install the replacement. Remove the old bulb clamp and fit the thermal bulb of the replacement valve to the evaporator outlet in the original location, using the new clamp provided with the new valve.

7 Open the liquid shut-off valve at the receiver.

8 Leak test the connections which have been disturbed.

9 Set the suction service valve to the operating position and start the plant.

10 Operate the plant until pressures have stabilized. Check the refrigerant charge via the sight glass and operating pressures.

11 Adjust the valve to give the recommended degree of superheating.

12 Remove gauges, cap service valves and carry out a final leak test.

13 Clear the site of debris, oil etc.

The system may be evacuated through the gauge port on the compressor. Crack off the suction service valve from the front seat position and allow a small amount of vapour to enter the compressor crankcase. Front seat the suction service valve again, slacken off the gauge port union and evacuate the compressor. After evacuating, set the suction service valve to the operating position and continue the above procedure at step 12.

If the valve is seized in a closed position the procedure will be the same as previously described.

When a valve is letting by or has lost part of its thermal charge, then the system must be pumped down before carrying out the procedure.

If an internal equalizing expansion valve is substituted with an external equalizing valve, an additional connection must be provided for the external equalizing capillary.

Assuming the restriction in the drier is only partial, and that a low pressure cut-out control is in circuit, the following procedure should be adopted:

1 Note the pressure at which the compressor cuts out. The control must be reset to the original setting after the filter drier is replaced.

2 Alter the range of the low pressure control and pump down the system as previously described. Ensure that the suction service valve is front seated when this is completed.

3 Isolate the plant electrically.

4 Remove the defective filter drier and replace it. Take care that the new one is installed correctly; note the direction of flow.

5 Open the liquid shut-off valve at the receiver.

6 Leak test the joints which have been disturbed.

7 Loosen the connection on the suction line at the inlet to the compressor and allow a small amount of vapour to escape, tighten connection.

8 Set the suction service valve to the operating position and operate the plant.

9 Reset the low pressure control to its original cut-out setting.

10 Remove gauges, fit service valve caps and carry out a final leak test.

11 Clear the site of debris etc.

Should the filter drier be completely blocked, which is improbable, then the replacement procedure will be the same as that given earlier for the replacement of a thermostatic expansion valve with a complete loss of charge.

The filter drier is described further in Chapter 12.

Low side purging is now considered to be bad practice and air in the system should be removed by using a vacuum pump to minimize refigerant loss to the atmosphere which in turn affects the ozone layer. The correct procedure to be adopted is given in the section dealing with reclaim and recovery of refrigerants.

When a system pipework is opened to atmosphere during a replacement operation, it is possible that air will enter the system. Air contains moisture, and only a small amount of moisture in a system which has a capillary for the refrigerant control can result in that moisture freezing. This leads to a complete loss of refrigeration.

Filter driers are normally capable of dealing with small quantities of moisture. However, it is recommended that a drier be changed when leaks are detected, especially on the low side.

A complete loss of the refrigerant charge owing to leakage can result in a compressor operating on vacuum, drawing in air. In this case the drier could become saturated and moisture will circulate through it. When this occurs, freezing can take place at the expansion valve; this is tantamount to a complete blockage in the liquid line.

When the symptoms of plant operation indicate a complete blockage, and no temperature difference is obvious at the filter drier, it is natural to suspect that the expansion valve or perhaps a solenoid valve is at fault. The simple expedient of applying a cloth dipped in hot water will determine the presence of moisture. Warming up the expansion valve will melt the ice in the valve and

the flow of refrigerant will resume, but only until such time as the temperature at the expansion valve is low enough to form ice and restrict the liquid flow once more. A blowtorch should never be used for this purpose, for obvious reasons.

In most cases, fitting a new filter drier will overcome the problem. However, it is stressed that this drier should be removed after a suitable running period and another new drier fitted. Should the condition persist after a drier has been replaced, the system must be discharged of refrigerant, evacuated and then recharged.

This is also referred to as a compressor pump test. It is carried out when the functions of the compressor suction and discharge valves are suspect; this will be indicated by high suction and low discharge pressures. The test should be carried out with the plant running at an operating head pressure of at least 100 psig or 6.5 bar if possible in order to prove the efficiency of the valves. The procedure is as follows:

1 Front seat the suction service valve and note the cut-out pressure of the low pressure control. The control must be reset to its original cut-out pressure after the test.

2 Alter the range of the low pressure control so that the compressor is drawing a vacuum.

3 Reduce the low side pressure to at least 20 in Hg vacuum or 0.7 bar.

4 Stop the compressor and observe the pressure rise on the compound gauge for 2 minutes.

If the suction reeds are seating properly and cylinder/piston wear is not excessive, the pull-down to a vacuum should be rapid. The front seating of the suction service valve isolates pressure coming from the evaporator, and only the compressor crankcase is being evacuated of the refrigerant vapour. A compressor is deemed reasonably efficient if the 20 in vacuum is achieved. If it is not possible to draw this vacuum, then the suction reeds are defective.

When a 20 in vacuum is achieved, the pressure rise should be minimal; the entire vacuum should not be lost over the 2 minute observation period. When the vacuum is drawn and the plant switched off, if a rapid rise in pressure is observed on the compound gauge then refrigerant vapour is leaking into the cylinder(s) via the discharge valve(s). The valves must be inspected for distortion of reeds or faulty seating.

On most compressors this will be a relatively simple task, but the procedure will differ with compressor design. The following is the procedure for a compressor with the valves in the head:

1 Start the plant, front seat the suction service valve and reduce the crankcase pressure to 3 psig or 0.2 bar if possible.

2 Stop the plant, isolate electrically and front seat the discharge service valve.

3 Slacken off the compressor head bolts slowly to release the high pressure from the discharge side of the head. Remove the bolts.

4 Gently raise the compressor head, with suction and discharge lines intact, sufficiently high to be able to withdraw the valve plate assembly. Care must be taken to avoid fracture of the pipework unions.

5 If the cylinder head and valve plate gaskets are damaged when the valve plate is removed, they must be replaced.

6 Distorted or broken reeds will obviously have to be replaced. Some manufacturers will recommend replacement of the entire valve plate assembly; replacement kits are available complete with gaskets.

Should the valve seats on the valve plate be eroded or pitted and a replacement is not readily available, they can be made serviceable by reseating or lapping. This is generally regarded as a workshop practice. The method is as follows:

1 Obtain some valve grinding paste or carborundum powder and some polishing compound. Spread a liberal amount of the paste on to a lapping block or a hard flat surface such as a polished steel plate or sheet of glass.

2 Remove the discharge reed retainers and reeds from the valve plate.

3 Place the valve plate on the pasted surface, exert a firm even pressure and move the valve plate in a figure-of-eight motion. Continue until the valve seats are returned to an original finish. When carborundum powder is used it should be mixed with refrigeration oil.

4 When reseating is complete, remove all traces of carborundum and paste from the valve plate with spirit or paraffin.

5 Repeat the operation with the polishing compound and clean as before.

6 Reassemble dry with new reeds if required. If the original reeds are used, they should be inverted so that the seat contact is made to the unused side of the reed.

The procedure for replacing the valve plate assembly is as follows. If gaskets are re-used they should be perfectly clean and dry.

Service diagnosis and repairs 53

1 Once the valve plate is located, replace the head bolts and screw them down finger tight.

2 Tighten the bolts diagonally across the head, care being taken not to overtighten and strip the threads.

3 Crack off the suction and discharge service valves from the front seat positions.

4 Leak test the compressor and pipework unions.

5 Purge the compressor through the gauge port unions.

6 Set the service valves to the operating positions and start the plant.

7 Operate the plant and observe pressures; these should now be normal.

8 Carry out the compressor pump test.

9 Reset the low pressure control.

10 Remove gauges, replace valve seal caps and wipe the compressor clean of oil.

11 Make a final leak test.

12 Clear the site.

Most smaller open drive and some direct drive semi-hermetic compressors employ this type of crankshaft seal. They are often a cause of noise complaints (squeaking) and refrigerant leaks. Generally this is due to lack of lubrication; when the seal surfaces are dry, wear and scoring of the polished facings occur.

In order to remove this type of seal it is necessary first to remove the compressor flywheel. The larger the compressor, the larger and heavier will be the flywheel. Extra care must be exercised when removing the larger types, which may be castings and easily damaged if dropped. Removal should not be attempted without a suitable extractor. Under no circumstances should a hammer be used to break the bond between shaft, keyway and flywheel boss (not for semi-hermetic compressors).

Systems must be pumped down and isolated electrically. The drive belt guards must be removed to gain access to the flywheel on units with water cooled systems or with a remote condenser. On smaller air cooled units the compressor must be removed from its base, and this is dealt with here.

1 Pump down the system, front seat both service valves and isolate the unit electrically.

2 Remove the head retaining bolts and gently raise the compressor head.

3 Withdraw the valve plate assembly and remove the suction reeds from the cylinders.

4 Remove the compressor mounting bolts and belt guard.

5 Slide the compressor body towards the drive motor, release the drive belts from the flywheel and remove the compressor body.

6 Release the locking device on the drive shaft. This could be in the form of two locknuts, a locknut and a tab washer, or a locknut and a pin.

7 Using a suitable extractor, locate the arms around the flywheel boss (avoid locating around the flywheel vee section). Never use a hammer to remove a flywheel.

8 Apply gentle pressure on the extractor to break the bond, then remove the flywheel. With large heavy types it is advisable to tie a rope or cord to the flywheel and secure it in case the bond breaks suddenly.

9 Remove the seal plate retainer bolts and seal plate. The seal will be released by spring pressure in most cases; withdraw the seal from the seal housing.

10 Remove the seal ring from the shaft.

It may be necessary to change the compressor oil when a seal replacement is made, or some oil may be lost during replacement.

The procedure for replacement is as follows. Some manufacturers supply a shaft centring tool to ensure that the seal is correctly aligned on the shaft; this also eliminates uneven pressure being applied by the seal plate and spring during assembly.

1 Locate the seal ring on to the shaft and push fully home to the shaft shoulder.

2 Dip the seal nose in refrigeration oil and locate over the shaft, using the centring tool if available.

3 Replace the seal plate, depressing evenly against the spring. Insert the retaining bolts, and tighten the bolts so as to maintain the correct alignment of the shaft seal assembly.

4 Reassemble the compressor, belts etc. in reverse order. Check the belt tensioning and the alignment of the drive option and flywheel.

5 When reassembly is complete, fit gauges if these have been removed to facilitate the replacement.

6 Crack off both service valves from the front seat positions and purge the compressor through the gauge port unions if there is sufficient refrigerant pressure in the system. If the charge was lost, then evacuate, fit a new filter drier, charge the system and check the oil level.

7 Carry out a leak test.

8 Start the plant and check the system operation.

9 Remove gauges.

10 Clean the compressor and clear the site.

This type of compressor does not have a flywheel or drive belts; the compressor is linked to the drive motor by means of a coupling. To gain access to the seal housing, this will have to be dismantled before the seal plate and seal assembly can be withdrawn. It may also be necessary to move the drive motor in order to remove the seal assembly.

Basically the foregoing procedures for removal and replacement remain the same, with the exception of the coupling alignment. A typical alignment is dealt with in Chapter 13.

This condition is probably more common than faults causing low suction pressures, especially during the summer months when ambient temperatures are higher. Causes and corresponding remedial actions are listed as follows.

Causes

Restricted air flow over the condenser is caused by:

1 Condenser fins blocked by an accumulation of dirt and debris drawn in by the condenser fan(s).

2 Inoperative condenser fan(s).

3 Air in the system if a leak has developed on the low side and the compressor has operated with suction pressures below atmospheric.

4 High ambient temperature.

5 An overcharge of refrigerant.

Remedies

1 The most effective method of cleaning condensers is by means of a liquid or foam application which penetrates the build-up of the undesirable deposits

on the coil and fin surfaces. Brushing the condenser can produce somewhat limited results because of inability to reach the entire surface area.

2 Replacement of fan(s) may be required, or failure may be due to a loose wire or broken electrical lead.

3 This can be verified by stopping the plant and allowing sufficient time for the condenser to cool to ambient temperature. Then refer to a pressure/temperature table and compare the standing or idle pressure with the pressure given by the table. If the idle pressure is higher than that given by the table, air or non-condensables are present in the system. Running condenser fans can speed up the cooling process.

4 High ambient conditions will require a survey of the installation and location of the condenser. Relocation may overcome the problem and provide larger volumes of fresh air. An extractor fan could be installed to remove the discharged air from the condenser, so preventing recirculation. When multiple units are installed, a baffle arrangement to route a fresh air supply over each condenser must be considered.

5 An overcharge of refrigerant cannot develop and must be the fault of the service or installing engineer. Check the standing or idle head pressure in the same manner as for air in the system. The pressure/temperature relationship should conform to the table. The excess refrigerant must be removed from the system.

Causes

Restricted water flow through the condenser is caused by:

1 Scaling of the interior surface of the condenser water tubing.

2 Incorrectly adjusted or defective water regulating valve.

3 Inadequate water supply: malfunction of recirculating water pump, resulting in poor supply and high water temperature.

4 Air in the system.

5 An overcharge of refrigerant.

Remedies

1 Descaling of condenser tubing can be carried out by brushing through the tubes of a shell and tube condenser. If the scale deposit is heavy, a chemical method is advisable. A shell and coil condenser can only be cleaned chemically. The cost of descaling must be compared with that of

a replacement. The cleaning of water cooled condensers is described later in this chapter.

2 Check the water inlet and outlet temperatures of the condenser and the water regulating valve operation.

3 Check the water supply pressure and volume.

4 Air or non-condensables present in a water cooled condenser system can be diagnosed very quickly. The water regulating valve, responding to the high operating head pressure, will be supplying a high volume of water to the condenser. When the plant is stopped, water will continue to flow and reduce the temperature of the refrigerant in the condenser. In a matter of minutes the temperature of the refrigerant will be the same as that of the water (the inlet and outlet temperatures will be equal). Compare the idle head pressure with that given in a pressure/temperature table; a higher than normal pressure denotes the presence of non-condensables.

5 Adopt the same procedure as in remedy 4.

If high operating head pressure conditions cannot be rectified by any of the foregoing, it must be considered that the condenser is undersized. It must be replaced, or a subcooler must be installed.

Like low side purging, the practice of purging from the high side is also unac- ceptable and must be discontinued. When it is certain that non-condensables are present in a system a leak test must be carried out on the entire system and the leak repaired. If a plant has been recently installed or it has been subject to service or repair it is possible that nitrogen could have been inadvertently left in the system. If air has entered the system in sufficient quantity the effect could possibly be of excessive operating head pressure similar to that of nitrogen left in the system. The removal of a non-condensable can be costly if the operating charge of refrigerant is large. The system would need to be completely discharged, evacuated and then re-charged.

A non-condensable gas will be lighter than refrigerant vapour and will rise to the top of a condenser/receiver when the plant is at rest. Removal of the non- condensable must take place at the highest point. Some condensers/receivers are fitted with a gauge connector or valve for this purpose. This connector may be in the form of a ‘purge screw’ on older type equipment. Removal of a non- condensable can easily be achieved via the gauge port on the high side of the compressor head. The system should be ‘pumped down’ and a short period of time allowed for the non-condensable to rise to the highest point. The procedure for removal is detailed in the section covering recovery/removal

The removal of non-condensables therefore should be carried out by using a vacuum pump. Purging air from a system charged with refrigerant would also release some of the refrigerant to the atmosphere.

It is the duty of any service or installation engineer to protect the environment by discontinuing the release of CFCs and HCFCs to the atmosphere whenever servicing or installing refrigeration equipment.

In the case of nitrogen being present in a system, this can be purged from both the low and high side.

Any type of water cooled condenser is prone to scaling of the interior surfaces of the water tubing. The rate at which the scale forms will depend upon the condensing temperature and the quality of the water circulated. Scaling will be relatively low where condensing temperatures are below 38 °C.

Shell and tube condensers are fitted with removable end plates to enable cleaning to take place by means of a wire brush. This is satisfactory for mild scale build-up, but heavy scale deposits may necessitate removal by chemical means.

Scale can be removed with descaling agents, which are available in both liquid and powder forms. Solutions of chemicals and water can be used as follows:

1 Muriatic acid 18 per cent and water 82 per cent for rapid descaling.

2 Hydrochloric acid 22 per cent and water 78 per cent for slower but equally effective action.

Descaling solutions can damage flooring, paintwork, clothing and plant life. They are obviously a health hazard, and contact with eyes and skin must be avoided. Adequate protective clothing must be worn, and precautions against spillage must always be taken.

When cleaning condenser coils or tubes the working areas must be well ventilated. A vent pipe is a vital part of the cleaning equipment; it will carry off the toxic fumes which are generated by the chemicals during the cleaning process.

In addition to scaling, water cooling systems are subject to corrosion from fumes given off by nearby industrial plant. Concentrations of sulphur and salts will be present in the atmosphere.

Systems installed in a coastal area are susceptible to corrosion by salt borne by the air.

There will always be the problem of algae growth and bacterial slime. These can only be controlled by regular cleaning and the use of various algaecides. Inhibitors such as Hydrofene have been used over a long period without any ill effect being observed.

Prolonged operation at high discharge pressures and temperatures, excessive motor starting, fluctuating voltage conditions, shortage of refrigerant charge and shortage of oil in the compressor are all possible causes of a motor burn-out.

A burn-out can be defined as the motor winding insulation having been exposed to a critical temperature for a long period.

This occurs with R12, R22 and R502 at temperatures in excess of 150 °C (302 °F). In the presence of hydrogen-containing molecules, thermal decomposition produces hydrochloric and hydrofluoric acids. Phosgene is

produced at very high temperatures, but this is decomposed in the presence of oxygen.

Bearing in mind the above, it is important to remove the entire refrigerant charge and reclaim the refrigerant for processing. A recognized reclaim refrigerant cylinder should be used and care taken not to overfill the cylinder.

When the windings insulation breaks down, very high temperatures occur at the short circuited location. In addition, a certain amount of moisture will be released from the windings assembly to further contaminate the system. Following a motor burn-out, the system must be decontaminated before a new compressor is fitted.

When the defective motor has been removed, a test should be made to determine the acid content of the compressor oil. Two methods may be used: litmus paper and burn-out test indicator. A sample of the oil from the defective motor compressor should be taken and tested. If the test indicates acid, then the refrigerant system must be flushed and tested as follows. Flushing is dealt with overleaf.

Litmus paper

Take a sample of the solvent after flushing and put it into a suitable container. Place the litmus paper in the liquid. If acid is present it will change colour, ranging from pink to red according to the degree of acidity in the sample. The system must then be flushed again and the test repeated.

Indicator

When testing with an indicator it is necessary to charge the system with the liquid solvent ready for flushing and allow to stand for 30 minutes. Then take samples of the solvent, if possible from both the high and the low side of the system.

Add the prescribed amount of indicator to the samples and agitate the mixture; examine for a colour change. The results and necessary actions are as follows:

1 If red or pink, strong acid content: flush again.

2 If orange or yellow, acid content: flush again.

3 If carbonized particles are present in the samples: flush again.

4 If lemon yellow, no acid content: system may be evacuated.

System flushing

When a system has been contaminated, especially following a hermetic motor compressor ‘burn out’, the past practice was to flush the system through with R11. This practice is no longer acceptable.

Approved burn-out filter driers are available these days to make flushing

unnecessary. Instead the system can be cleansed by installing suitable filter driers and carrying out a triple evacuation (see Chapter 16, Dilution method). The filter driers will absorb moisture and acid content from the system pipework.

During the evacuation of the system, evaporator fans and electric defrost heaters may be switched on to raise the temperature of the evaporator. However, extreme care must be taken to avoid overheating by the defrost heaters.

After a system has been repaired and evacuated, burn-out driers installed, leak tested and charged with refrigerant it should be operated for a period of 24 hours. An acid test should then be carried out and, if satisfactory, the burn-out driers can be removed and exchanged for normal filter driers. When an acid test reveals contamination new, burn-out driers must be installed and the process repeated.

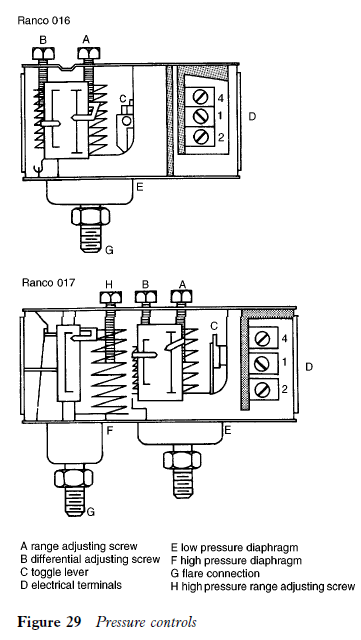

There are many different makes of pressure controls. Designs may vary but the principle of operation is basically the same: single pressure models respond to either low or high pressure; dual pressure versions can be activated by both high and low pressures.

Pressure controls are installed to perform a variety of functions. Most current production controls are designed with three electrical terminals. These enable the control to be used to open an electrical circuit upon a rise in pres- sure or upon a fall in pressure, depending on the application. Unfortunately, identification of the electrical terminals is not standard, and it is important to know which of the three is the common terminal.

Single pressure controls have two adjusting screws: the range and the differ- ential. Dual pressure versions have three screws: the range and differential for low pressure operation, and a range screw for high pressure operation. This differential is preset at 50 psi or 3.5 bar.

The controls described are commonly employed and will serve to identify adjusting screws and electrical terminals.

A low pressure control may be used as:

1 A temperature control.

2 A safety cut-out to prevent overcooling or overfreezing of a product.

3 A defrost termination control to open the circuit to defrost heaters should the evaporator become completely free of frost before the defrost period has elapsed. This prevents undue pressure build-up in the evaporator.

4 A compressor cut-out when operating on a pump-down cycle.

A high pressure control is employed as a safety cut-out for the compressor in the event of excessive operating pressures developing on the high side of the system during operation. Table 4 shows the settings required.

Figure 29 shows two typical controls. The details are as follows.

Ranco type 016: low pressure operation

To complete an electrical circuit on rise in pressure, terminals 1 and 4 must be used. To complete an electrical circuit on fall in pressure, terminals 1 and 2 must be used.

The control range is 12 in Hg vacuum to 100 psi (0.4 to 7 bar).

Ranco type 017: dual pressure operation

The control range is 12 in Hg vacuum to 100 psi (0.4 to 7 bar) on the low pressure side, and 100 to 400 psi (7 to 26.5 bar) on the high pressure side. The high pressure automatic reset differential is 50 psi (3.5 bar).

For low pressure control:

1 Adjust the range screw A until the compressor cuts in at the selected pressure.

2 Adjust the differential screw B to stop the compressor at the desired cut-out pressure.

For high pressure control, adjust the range screw H to a selected cut-out pres- sure and the control will reset automatically.

Check the control operation several times after final adjustments have been made.

Always adjust controls with a pressure gauge, using the graduated scales as a guide only. Never lever the control mechanism to actuate it; this can

This procedure can be followed for setting any make of control, such as those in Figure 30.

When locking plates are provided, set the control, replace the locking plate to secure the differential screw, and fit the knob to the range screw.

Low pressure control adjustments can be made by front seating the suction service valve to reduce the pressure on the low side of the system.

High pressure control adjustments must be made by increasing the operating head pressure, i.e. by blocking off the condenser, thereby restricting the air flow, or by switching off condenser-fans. The head pressure can be quickly increased on water cooled units by shutting off the water supply.

It is dangerous practice to increase the head pressure by front seating the discharge service valve.

The examples in Figure 31 illustrate the effects of a reduced range and differential setting with a low pressure control.

Motor cycling controls: thermostats

Two types of thermostat are commonly used to control the temperature of a refrigerated space or product by stopping and starting the compressor.

The most popular is the vapour pressure type. This consists of a small bulb or sensing element containing a very volatile liquid charge. The liquid has the ability to vaporize at low temperatures. When the bulb is subjected to a rise in temperature, the pressure generated by the vaporizing liquid will increase.

A capillary connects the bulb to a bellows or diaphragm. The vapour pressure causes the bellows to expand or the diaphragm to flex and operate the switch mechanism, closing the contacts to start the compressor motor. As the sensing element or bulb cools, the pressure in the bellows or diaphragm will decrease. The bellows will contract or the diaphragm will return to its normal position, thus opening the electrical contacts to stop the compressor.

Switch mechanisms have some form of toggle action or a permanent magnet device to ensure rapid and positive make or break of the switch contacts. This prevents arcing, which occurs when electrical current jumps across the minute gap between the contacts. Figure 32 shows toggle and permanent magnet switch arrangements.

The permanent magnet snap action type has a switch contact arm made of a magnetic material (iron or steel), and the magnet attracts the arm towards it. The pressure from the sensing element acts against the magnetic attraction to close the contacts according to the temperature of the element or bulb. As the arm moves closer to the magnet, the magnetic effect increases to cause the snap action.

When the sensing element cools and the switch bellows contract, some force is necessary to open the contacts. However, the magnetic force decreases as soon as the contacts break to allow rapid opening.

The compound bar type of thermostat, more generally called a bimetal element, comprises two dissimilar metals, usually Invar and brass or Invar and steel. Invar is an alloy which has a very low coefficient of expansion, whilst brass and steel have a relatively high coefficient of expansion. When an increase or decrease of temperature is sensed by the bimetal element the length of the Invar will cause the bimetal to warp. This warping action is utilized to open and close the switch contact (Figure 33).

Thermostats have range and differential adjustments which can be altered in the same manner as previously described for pressure controls. Electrical terminal arrangements will obviously differ by manufacturer, and reference should be made to the literature supplied with the controls.

Some domestic appliance thermostats have a two-way switching feature in their design. When cooling is no longer required and the cut-out point of the

switch is reached, the contacts to the compressor are opened and the contacts to a defrost heater are closed. This achieves automatic defrosting after every on cycle, to keep a minimal frost build-up on the evaporator at all times for more efficient operation.

Sealed systems such as domestic refrigerators and freezers need to be treated differently, since there may not be provision for fitting gauges unless line tap valves are used.

If the temperature control is by thermostat only and there is no low pressure safety control, continuous running of the unit will result if the system:

1 Is short of refrigerant or has a restriction in the liquid line.

2 Is operating in a high ambient temperature or with restricted air flow over the condenser.

3 Has a faulty fixture door seal, imposing a high evaporator load.

4 Has excessive frost build-up on the evaporator.

5 Is operating with a defrost heater in circuit (has a defective timer), giving a high evaporator load.

Domestic system repairs will be dealt with in detail in Chapter 8.

The sources of noise are numerous, and in some cases are entirely dependent upon the location and the type of building structure.

Common sources of noise are as follows:

1 Line rattles, that is pipework or control tubing vibrating against an evap- orator or condenser shroud or framework.

2 Items of stored products (metal containers) or storage shelves vibrating.

3 Evaporator or condenser fan mountings loose.

4 Condensing unit base mountings or mounting frame loose; inadequate noise suppression from mounting fabric used (Tico pads, for example).

5 Perished rubber mounting grommets, which are especially prone to dete-

rioration if contaminated with oil and refrigerant.

6 Gas pulsations against a rigid pipework design, creating a noise source during operation or when the compressor starts and stops.

7 Incorrect belt tension or belt and drive pulley alignment with open-type condensing units.

A better assessment of noise problems can be made after a study of the pipework design and installation recommendations (Chapter 10).

In order to diagnose any refrigeration fault quickly and accurately, a set procedure must be followed. The procedure described here takes the form of seven simple steps. If fully understood, these will prevent expensive call-backs and dissatisfied customers. No attempt to correct a condition should be made until the fault has been found, and therefore a thorough diagnosis is essential.

It is necessary to have the correct tools and instruments with which to carry out the procedure. These include a resistance thermometer, a leak detector, gauges, valve keys, a multitester or avometer and a compressor test cord, together with a complete set of engineering tools.

The seven steps are as follows:

1 Check the actual temperature of the product and compare with that recommended for the product.

2 Check the suction pressure, control switch settings and product classification to establish the temperature difference (TD) between the evaporator and the product.

3 Check the superheat setting of the expansion valve.

4 Check the condensing medium temperature.

5 Check the operating and idle head pressures of the compressor.

6 Check the refrigerant type and charge.

7 Check the drive pulley size on an open type system. If the compressor is hermetic or semi-hermetic, check the operating range; they may be for high, medium or low back pressure operation.

An incorrect size of pulley may be fitted to a drive motor. The refrigerating effect may be acceptable in cooler ambient temperatures, but when ambient temperatures rise the equipment will not have the capacity because of the compressor speed.

The same principle applies to the compressor operating range; older models were selected for specific operating conditions.

The following practical sequence is suggested for covering the first six steps:

(a) Ensure that the product has been stored for sufficient time to have become chilled or frozen (has not recently been deposited) before checking the product temperature. Take the actual temperature of the product and not the air circulating around it. Take care that the temperature has not been affected by the opening of the fixture door.

Service diagnosis and repairs 73

(b) Fit gauges and calculate the average suction pressure to establish the TD (see Chapter 5). Consult the classification in Chapter 5 to establish the product group, and note the TD for the type of evaporator employed in the system. If the TD is incorrect, an adjustment of the temperature control may be all that is necessary to rectify the fault.

(c) Ensure that the system has been operating for a sufficient period to be at an average suction pressure, and check the refrigerant charge. Check the operating head pressure and the idle head pressure. Check the superheat setting of the expansion valve. When checking the refrigerant charge, observe the condition of the evaporator (should be fully frosted) and the liquid sight glass. Do not adjust the expansion valve unless the refrigerant charge is complete and the system is operating at an average suction pressure.