Safety is a subject of utmost importance to all technical personnel. Potentially hazardous situations exist in almost any work area. The disregard of safety precautions can result in personal injury or in the loss of equipment or equipment capabilities.

In this section we will discuss two types of safety factors. First, we will cover damage that can occur to electronic components because of electrostatic discharge (ESD) and improper handling and stowage of parts and equipment. Second, we will cover personal safety precautions that specifically concern the technician.

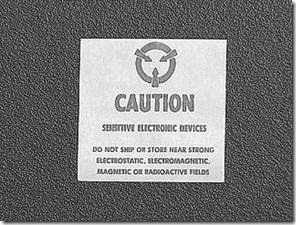

Electrostatic discharge (ESD) can destroy or damage many electronic components including integrated circuits and discrete semiconductor devices. Certain devices are more susceptible to ESD damage than others. Because of this, warning symbols are now used to identify ESD-sensitive (ESDS) items (figure 3-31).

Figure 3-31.—Warning symbols for ESDS devices.

Static electricity is created whenever two substances (solid or fluid) are rubbed together or separated. This rubbing or separation causes the transfer of electrons from one substance to the other; one substance then becomes positively charged and the other becomes negatively charged. When either of these charged substances comes in contact with a conductor, an electrical current flows until that substance is at the same electrical potential as ground.

You commonly experience static build-up during the winter months when you walk across a vinyl or carpeted floor. (Synthetics, especially plastics, are excellent generators of static electricity.) If you then touch a door knob or other conductor, an electrical arc to ground may result and you may receive a slight shock. For a person to experience such a shock, the electrostatic potential created must be 3,500 to 4,000 volts. Lesser voltages, although present and similarly discharged, normally are not apparent to a person's nervous system. Some typical measured static charges caused by various actions are shown in table 3-2.

Metal oxide semiconductor (MOS) devices are the most susceptible to damage from ESD. For example, an MOS field-effect transistor (MOSFET) can be damaged by a static voltage potential of as little as 35 volts. Commonly used discrete bipolar transistors and diodes (often used in ESD-protective circuits), although less susceptible to ESD, can be damaged by voltage potentials of less than 3,000 electrostatic volts. Damage does not always result in sudden device failure but sometimes results in device degradation and early failure. Table 3-2 clearly shows that electrostatic voltages well in excess of 3,000 volts can be easily generated, especially under low-humidity conditions. ESD damage of ESDS parts or circuit assemblies is possible wherever two or more pins of any of these devices are electrically exposed or have low impedance paths. Similarly, an ESDS device in a printed circuit board, or even in another pcb that is electrically connected in a series can be damaged if it provides a path to ground. Electrostatic discharge damage can occur during the manufacture of equipment or during the servicing of the equipment. Damage can occur anytime devices or assemblies are handled, replaced, tested, or inserted into a connector.

Technicians should be aware of the many sources of static charge. Table 3-3 lists many common sources of electrostatic charge. Although they are of little consequence during most daily activity, they become extremely important when you work with ESD material.

Prevention of ESD Damage

Certified 2M technicians are trained in procedures for reducing the causes of ESD damage. The procedures are similar for all levels of maintenance. The following procedure is an example of some of the protective measures used to prevent ESD damage.

1. Before starting to service equipment, the technician should be grounded to discharge any static electric charge built up on the body. This can be accomplished with the use of a test lead (a single-wire conductor with a series resistance of 1 megohm equipped with alligator clips on each end). One clip end is connected to the grounded equipment frame, and the other clip end is

touched with a bare hand. Figure 3-32 shows a more refined ground strap which frees both hands for work.

Figure 3-32.—ESD wrist strap.

2. Equipment technical manuals and packaging material should be checked for ESD warnings and instructions.

3. Prior to opening an electrostatic unit package of an electrostatic sensitive device or assembly, clip the free end of the test lead to the package. This will cause any static electricity which may have built up on the package to discharge. The other end remains connected to the equipment frame or other ESD ground. Keep the unit package grounded until the replacement device or assembly is placed in the unit package.

4. Minimize handling of ESDS devices and assemblies. Keep replacement devices or assemblies, with their connector shorting bars, clips, and so forth, intact in their electrostatic-free packages until needed. Place removed repairable ESD devices or assemblies with their connector shorting bars/clips installed in electrostatic-free packages as soon as they are removed from the equipment. ESDS devices or assemblies are to be transported and stored only in protective packaging.

5. Always avoid unnecessary physical movement, such as scuffing the feet, when handling ESDS devices or assemblies. Such movement will generate additional charges of static electricity.

6. When removing or replacing an ESDS device or assembly in the equipment, hold the device or assembly through the electrostatic-free wrap if possible. Otherwise pick up the device or assembly by its body only. Do not touch component leads, connector pins, or any other electrical connections or paths on boards, even though they are covered by conformal coating.

7. Do not permit ESDS devices or assemblies to come in contact with clothing or other ungrounded materials that could have an electrostatic charge. The charges on a nonconducting material are not equal. A plastic storage bag may have a -10,000 volt potential 1/2 inch from a +15,000 volt potential, with many such charges all over the bag. Placing a circuit card inside the bag allows the charges to equalize through the pcb conductive paths and components, thereby causing failures. Do not hand an ESD device or assembly to another person until the device or assembly is protectively packaged.

8. When moving an ESDS device or assembly, always touch (with bare skin) the surface on which it rests for at least one second before picking it up. Before placing it on any surface, touch the surface with your free hand for at least one second. The bare skin contact provides a safe discharge path for charges accumulated while you are moving around.

9. While servicing equipment containing ESD devices, do not handle or touch materials such as plastic, vinyl, synthetic textiles, polished wood, fiberglass, or similar items which create static charges; or, be sure to repeat the grounding action with the bare hands after contacting these materials. These materials are prime electrostatic generators.

10. If possible, avoid repairs that require soldering at the equipment level. Soldering irons must have heater/tips assemblies that are grounded to ac electrical ground. Do not use ordinary plastic solder suckers (special antistatic solder suckers are commercially available).

11. Ground the leads of test equipment momentarily before you energize the test equipment and before you probe ESD items.

Work benches on which ESDS items will be placed and that will be contacted by personnel should have ESD protective work surfaces. These protective surfaces should cover the areas where ESD items will be placed. Personnel ground straps are also necessary for ESD protective work bench surfaces. These straps prevent people from discharging a static charge through an ESDS item to the work bench surface. The work bench surface should be connected to ground through a ground cable. The resistance in the bench top ground cable should be located at or near the point of contact with the work bench top. The resistance should be high enough to limit any leakage current to 5 milliamperes or less; this is taking into consideration the highest voltage source within reach of grounded people and all parallel resistances to ground, such as wrist ground straps, table tops, and conductive floors. See figure 3-33 for a typical ESD ground work bench.

Energized equipment provides protection from ESD damage through operating circuitry. Circuit cards with ESD sensitive devices are generally considered safe when installed in an equipment rack; but they may be susceptible to damage if a "drawer" or "module" is removed and if connector pins are touched (even putting on plastic covers can transfer charges that do damage). There must not be any energized equipment placed on the conductive ESD work surface. An ESD work area is for "dead" equipment ONLY.

ESD protection is critical. If you should be assigned to 2M repair school, your education in ESD prevention will be quite extensive.

Throughout your career you will be aware of emphasis placed on safety. Safety rules remind you of potential dangers in work. Most accidents are preventable. Accidents don't happen without a cause. Most accidents are the result of not following prescribed safe operating procedures.

This would be a good time to review the safety section in topic 5 of NEETS, Module 2, Introduction to Alternating Current and Transformers. That section covers the basics of electrical shock and how to prevent it.

The 2M technician should be aware of other potential dangers in addition to the dangers of electrical shock. These dangers are discussed in the following paragraphs.

Hazards associated with the use of power tools include electrical shock, cuts, and particles in the eye. Safe tool use practices reduce or eliminate such accidents. Listed below are some of the general safety precautions that you should observe when your work requires the use of power tools.

Soldering Iron

When using a soldering iron, remember the following:

The technician who smokes while using a cleaning solvent is inviting disaster. Unfortunately, many such disasters have occurred. For this reason, the Navy does not permit the use of gasoline, benzine, ether, or like solvents for cleaning since they present potential fire or explosion hazards. Only nonvolatile solvents should be used to clean electrical or electronic apparatus.

In addition to the potential hazard of accidental fire or explosion, most cleaning solvents can damage the human respiratory system where the fumes are breathed for a period of time.

The following positive safety precautions should be followed when performing cleaning operations.

Where water compounds cannot be used, inhibited methyl chloroform (1.1.1 trichloroethane) should be used. Carbon tetrachloride is not used. Cleaning solvents that end with ETHYLENE are NOT safe to use. Methyl chloroform is an effective cleaner and is as safe as can be expected when reasonable care is exercised, such as adequate ventilation and the observance of fire precautions. When using inhibited methyl chloroform, avoid direct inhalation of the vapor. It is not safe for use, even with a gas mask, because its vapor displaces oxygen in the air.

A 2M technician will encounter several uses for aerosol dispensers. The most common type is in applying conformal coatings.

Specific instructions concerning the precautions and procedures that must be observed to prevent physical injury cannot be given in this section because of the many available industrial sprays. However, all personnel concerned with handling aerosol dispensers containing volatile substances must clearly understand the hazards involved. They must also understand the importance of exercising protective measures to prevent personal injury. Strict compliance with the instructions printed on the aerosol

dispensers will prevent many accidents that result from misapplication, mishandling, or improper storage of industrial sprays.

The rules for safe use of aerosol dispensers are listed below:

Q34. List two causes of damage to ESD-sensitive electronic components. Q35. What is the purpose of the wrist ground strap?

Q36. What is the cause of most accidents?

Labels: Introduction to Microelectronics