Answers to questions and summary of miniature and micro miniature repair procedures

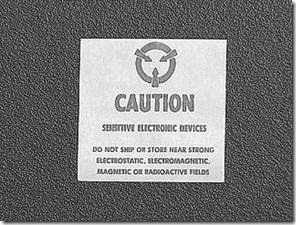

SUMMARY This topic has presented information on miniature and microminiature (2M) repair procedures and 2M safety precautions. The information that follows summarizes the important points of this topic. C O NF O R MAL COATINGS are protective materials applied to electronic assemblies to prevent damage caused by corrosion, moisture, and stress. C O NF O R MAL COATINGS REMOVAL is accomplished mechanically, chemically, or thermally, depending on the material used. Component LEAD S are terminated either through the board, above the board, or on the board. S O LDE R may be removed by wicking, by a manual vacuum plunger, or by a continuous vacuum solder extractor. ELECTR O N IC ASSEMBLIES should be restored to the original manufacturer's standards using the same orientation and termination method. A GOOD SOLDER JOINT is bright and shiny with no cracks or pits. When REPLACING DIPs , TOs , AND FLAT PACKS , make certain that pins are placed in the proper position. C O ...