Dc generators : generator field structures, armature reaction and buildup of self-excited fields

19–3 GENERATOR FIELD STRUCTURES

DC generators can be classified by the method used for providing the magnetic field. This classification can be tabulated like this:

1. Permanent-magnet generators

2. Separately excited generators

3. Self-excited generators

a. Shunt generators

b. Series generators

c. Compound generators

Permanent-magnet generators are reserved for a few low-power applications where control of field strength is not needed. Such constant-field generators are useful in control devices or circuits. In such applications, use is made of the permanent magnet generator’s characteristic to deliver a voltage output proportional to its speed.

Permanent-magnet generators are also known as magnetos and find applications with the electrical systems of motorcycles, small tractors, lawn mower engines, and the like.

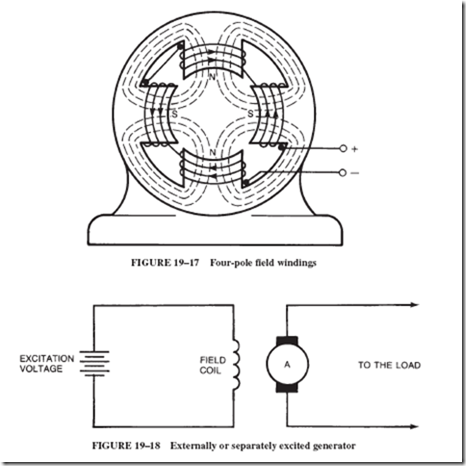

The field structure of a permanent-magnet generator is similar in design to that shown in Figure 19–1. Generally, though, electromagnets are used instead of permanent magnets. In this case, the circular frame, or yoke, is fitted with laminated iron pole pieces to accommodate the field winding, as illustrated in Figures 19–16 and 19–17.

Look at these drawings and note how the magnetic poles are developed in accordance with the left-hand rule for coils and the direction of the electron current. Furthermore, note that the magnetic circuit is completed by the iron yoke, or frame, which carries and concentrates the lines of magnetic flux. Note the positive and negative polarity marking on the wires that supply the field coils. It is the electric polarity of the power source that determines the direction of the current flow and, therefore, the orientation of the magnetic poles.

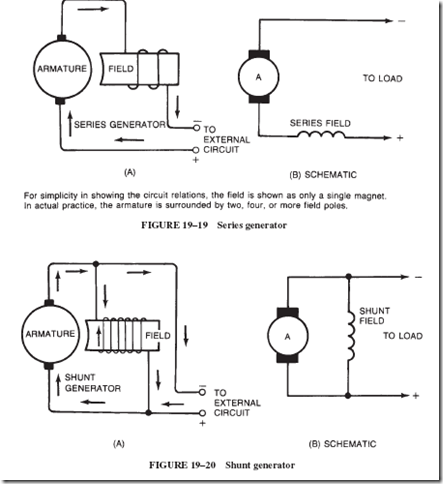

This is shown by the schematic diagram in Figure 19–18. If these field coil wires are attached to a storage battery or to a rectifier, the generator is an externally excited or a separately excited generator.

Field Connections for Self-Excited Generators

There are three possible field connections for self-excited generators, energized by current generated in the armature of the same machine.

1. Series: The field coils can be in series with the external load circuit. Series coils consist of relatively few turns of large wire, since they must carry the entire output current. Of the three types, this series generator is used least often; see Figure 19–19.

2. Shunt (or parallel): The field coils are connected across the brushes of the generator, which puts the coils in parallel with the external load. Shunt coils consist of a large number of turns of small wire and carry only a small current; see Figure 19–20.

3. Compound: The field-magnet iron is magnetized by the combined effect of two sets of coils. One set of low-resistance coils is in series with the external load circuit, and one set of high-resistance coils is in parallel with the load circuit.

In both of the compound generators shown in Figures 19–21 and 19–22, the series field aids the shunt field in magnetizing effect. This is the usual arrangement, called cumulative compounding. In a less common arrangement called differential compounding, the fields are connected so that they oppose each other.

19–4 ARMATURE REACTION

Ideally, the magnetic field in a generator has a straight, uniform pattern, as shown in Figure 19–23A. But the current generated in the armature causes another magnetic field, shown in B. Both magnetic fields combine (main field and armature field), making the total magnetic field take the direction shown in C. The distortion, or bending, of the main magnetic field of the generator, caused by the magnetic field of the current in the armature, is called armature reaction. Unless the distortion is corrected when the armature is producing current, the actual field in the generator is twisted, as shown in Figure 19–23D.

The Ill Effects of a Twisted Field

The bunching of the lines at the corners of the field poles causes an irregularity in the voltage output. More importantly, the field iron is not used effectively, and the total flux is less, making the average voltage output low.

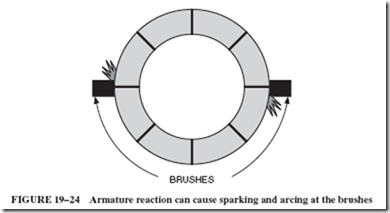

Furthermore, the twisted field changes the timing of the current reversals in the armature coils. In the explanation of Figures 19–13 and 19–14, it is stated that no harm is done by the brushes at certain instants when emf is not generated in the coil connected to the pair of segments involved. That statement is true only if the magnetic field is not disturbed. When the field is distorted, there is an emf between the commutator segments at the instant when both touch the same brush. This emf generates a brief, high current that causes excessive sparking and arcing as the commutator rotates; see Figure 19–24.

Remedies

Rotation. The first remedy used for field distortion was to rotate the brush holder by an equal amount to the twisting of the field. The rotation caused commutator segments to break contact with the brush at the instant of no emf. This remedy was unsatisfactory

because the amount of the field distortion changes whenever the armature current (load current) changes. To improve commutation in a generator, the brush holder is turned forward in the direction of rotation of the armature. To improve commutation in a motor, the brush holder is turned backward.

Interpoles. A better remedy is the addition of small field poles, called interpoles, or commutating poles, between the main field poles. Previous sketches show the armature current causing a vertical upward flux that tips the main magnetic field. The interpoles create another downward flux that tends to tip the main field back where it belongs. The interpole coils of the generator are connected into the circuit so that the interpoles have the same polarity as the main poles directly ahead of them (ahead in the sense of direction of armature rotation). In Figure 19–25, if rotation is reversed, the polarity of the interpoles must be reversed also.

To make the strength of the interpoles appropriate for their changing duty as the armature and load current changes, the interpoles are energized by coils in series with the armature. They therefore carry the same current as the armature. Since interpoles take care of the commutator difficulties, stationary brush holders can be used, with the brushes at the geometrical axis as shown originally.

Compensating Winding. However, these interpoles overcome field distortion only in their immediate neighborhood; much of the overall field-weakening effect is still present.

Large generators carry their output current through a few wires lying in the pole face placed parallel to the armature wires. This pole-face winding, called a compensating winding, is the most complete way of overcoming the field-weakening effect of armature reaction.

Advantages. Armature reaction can actually be advantageous in generators that must operate over a wide range of speeds. An example of this would be the DC generators that were used in automobiles of the 1920s through the 1950s. Consider the wide range of speeds encountered in a car engine. When field strength is constant, emf is proportional to rpm, a condition highly undesirable in the automotive generator. However, at moderate current output, the armature current distorts and weakens the average field sufficiently to help keep the emf at a reasonable value at high speed.

19–5 BUILDUP OF SELF-EXCITED FIELDS

The successful starting up of a generator depends on the existence of residual magnetism in the field iron; that is, a little magnetism remains from the effect of previous current in the field coil. When the armature of a shunt or compound generator starts rotating, a very low voltage is generated in the armature. This voltage is caused by the weak field in which the armature rotates. The low voltage causes a small current in the shunt field coils, increasing the strength of the field slightly. The increased field strength, in turn, causes the generated voltage to increase slightly. This increase causes more current in the field, increasing the field strength and therefore the armature voltage still more. The maximum amount of voltage, current, and field strength that can be built up is shown on the graph in Figure 19–26.

The magnetization curve, like that shown in Figure 19–26, shows the increase in field strength as the field current increases. Assume we have a generator, rated 120 volts output, that has a 40-ohm field coil. When the generator is started, the magnetization starts at a point above the zero line. This point represents a residual flux density of, say, 5,000 lines per square inch. According to the scales at the left, 5,000 lines per square inch cause a generated voltage of 7.5 volts when the armature is rotating at rated speed. The small current in the field (I 5 7.5/40 5 0.19 amperes) adds to the field strength, and the buildup continues to a field strength of 80,000 lines per square inch. By this time, the generated 120 volts is putting 3 amperes through the field. This 3-ampere current is needed to maintain the field at 80,000 lines per square inch in order for the 120 volts to be generated. At 3 amperes, because no more than 120 volts can be generated, the buildup stops. This limit is indicated by the resistance line on the graph. (Points on this resistance line give values of volts and amperes for 40-ohm resistance.)

The previous condition assumes constant speed. The generator output can be in- creased or decreased by increasing or decreasing the rpm. Also, the operating voltage of this shunt generator can be lowered to some other value (possibly 100 volts) by putting a little more resistance in the field circuit by using a rheostat in series with the field coil. Voltage output on a shunt generator is commonly controlled by such a field rheostat.

Failure to Develop Voltage

A generator without residual magnetism will fail to build up the magnetic field that is necessary to develop an output. Any of the following conditions may cause a self- excited generator to fail in producing the desired voltage:

• The direction of rotation may be such that it produces a magnetic field in the same direction as the residual magnetism. If the rotation is accidentally reversed, the generated field will oppose the residual magnetism and thereby obliterate it.

• A generator should not be started under load. If a load is attached before the generator develops its rated output, the terminal voltage may drop enough to cause a corresponding reduction in the field current, which in turn may cause a further decrease in the terminal voltage. This cycle of events continues until there is virtually no voltage output.

• Almost all generators have a rheostat connected in series with their shunt field winding for changing the output voltage by varying the field strength (excitation). Such a rheostat should be adjusted to its minimum resistance value during the start-up process, while the generator is building up its field.

• Also, accidental application of alternating current (AC) to the field coils will result in the loss of the residual magnetism that is so necessary for the buildup of the generator’s field. (Recall from Chapter 15 that AC acts as a demagnetizer.) In the event that the residual magnetism has been lost, it can be restored by a process known as flashing the field. This procedure requires a separate DC source to be applied briefly to the field coils. The voltage used for flashing the field should be nearly as high as the rated voltage for the generator. A 10- to 20-second application is generally sufficient.